The information supplied in this post is for advice only. Not all cleanrooms will use precisely the same strategies. Adhere to your specific cleanroom or business procedural handbook prior to this guidebook.

Facilities that utilize these Innovative aseptic processing strategies are previously in Procedure. In amenities where personnel are actually completely excluded with the significant zone, the necessity for room classification according to particulate and environmental microbiological monitoring needs could possibly be significantly diminished.

Corrective and Preventive Steps: Applying actions to eliminate or cut down the risk of contamination, like adjustments in operational protocols and devices.

We do not endorse these article content, we're neither affiliated with the authors of such articles or blog posts nor liable for their content material. Make sure you see our disclaimer part for complete phrases.

Machines Structure—Graphical illustration of an aseptic processing procedure that denotes the connection involving and between tools and staff. This structure is Utilized in the chance Evaluation Analysis to determine sampling site and frequency of sampling determined by possible for microbiological contamination with the merchandise/container/closure process.

Methodology: Protection products/attributes like Hearth extinguisher, Crisis exit door and breakable fireplace alarm window/ doors and many others. shall be discovered within the format.

In the long run, the check of any validation system is whether or not scientific information reveals the procedure constantly does as expected and generates a final result that continuously satisfies predetermined requirements.

Alternatively, to be able to include a safety margin, a combination of possible circumstances can be used. Examples may include frequent get started and end sequences, unanticipated maintenance of processing procedure, alternative of filters, etc. The qualification of an aseptic procedure need not be accomplished for every item, but must be completed for each processing line.

Screening and consulting around the explosion pitfalls related to equipment and procedures which use or produce hydrogen

The prevalent usage of isolator techniques for read more sterility testing has demonstrated that elimination of personnel does cut down contamination in aseptic dealing with.

If some one particular has no specification for fungal contamination, his facility will probably be observed uncontrolled one or another day as fungi are spore forming and not easy to sanitize by prevalent fumigation agent.

The swab is then rinsed in sterile saline or other acceptable menstruum as well as the contents plated on nutrient agar plates to acquire an estimate on the viable microbial load on that floor.

I concur that there's no point out of fungal rely in almost any on the guidelines, read more Nevertheless it's have to to get internal technical specs of fungal depend as NIL.

Numerous commercially available samplers are mentioned for informational applications. The selection, appropriateness, and adequacy of utilizing any certain sampler would be the accountability from the person.

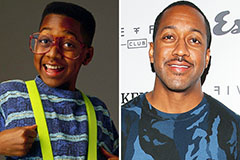

Jaleel White Then & Now!

Jaleel White Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!